What we aim to do.

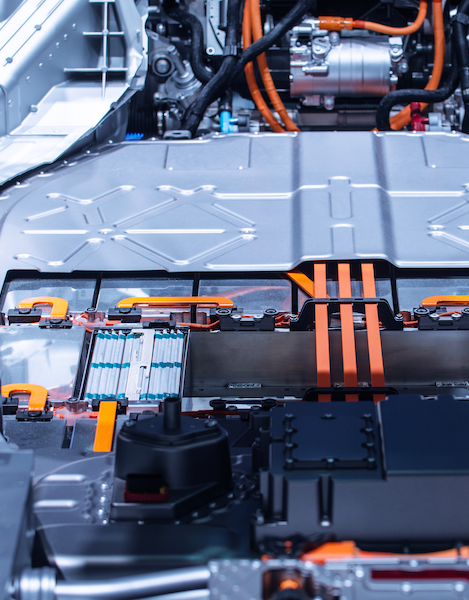

To date, the battery market is dominated by lithium-ion (Li-ion) chemistries, as the energy density has more than doubled and their costs have dropped by a factor of at least 10. However, conventional Li-ion batteries are reaching their performance limits in terms of energy density and additional features are needed to ensure safe batteries.

Development and production of new battery generations.

New battery generations is required, such as Solid-State Batteries (SSBs) as well as the creation of a new industry value chain in Europe towards their commercialization. To do so, the development and deployment of new manufacturing technologies, enabling the large-scale production of SSBs, is crucial.

Therefore, it is key to develop next solid-state battery generations with innovative and scalable manufacturing techniques to accelerate cost reduction, energy savings, and enhanced safety and enable its implementation in commercial applications

The proposed solution

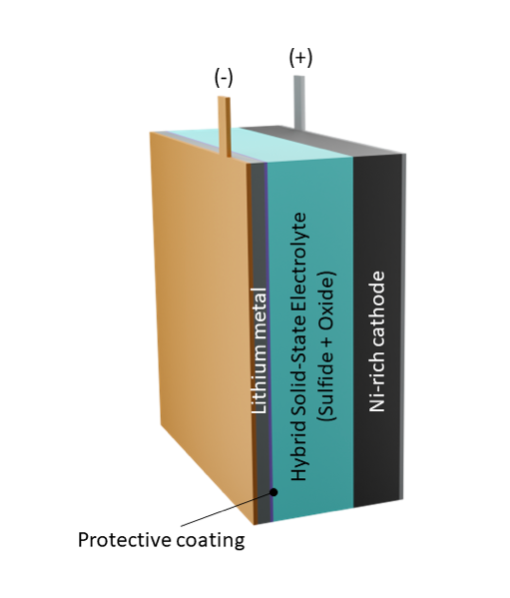

The ADVAGEN project will do so by developing a novel lithium metal (LiM) battery cell technology based on high performing hybrid solid-state electrolyte (oxide-sulfide based), which will be safer and more reliable.

Therefore, the aim is to gain a technological advantage over the current world market, especially Asian competition. Hence, sustainably strengthening the EU as a technological and manufacturing leader in batteries as specified in the ERTRAC electrification roadmap and SET-Plan Action Point-7.

Project and technology.

The main objective of ADVAGEN is to develop, manufacture and validate the most performant, stable, and safe 10 Ah solid-state pouch cells by developing novel materials for each of the parts that constitute a battery (i.e., the electrolyte, anode and cathode). In particular, an innovative hybrid oxide-sulfide ceramic electrolyte to be integrated with a lithium metal anode and a high Ni-rich content-based cathode.

Given that the ADVAGEN consortium covers the full battery value chain, it is in an excellent position to successfully conceive significant battery developments, as well as to adequately produce and test these results in a small scale and ramp up to production to find a use case in the EV industry. Moreover, the recycling process developed for the ADVAGEN solid-state batteries will develop a circular economy.

Impact

The developed technology within the ADVAGEN project aims to have an impact:

- To increase global competitiveness of the European battery ecosystem through generated knowledge and leading-edge technologies in battery materials, cell design, manufacturing and recycling

- By accelerating the growth of innovative, competitive, and sustainable battery manufacturing industry in Europe.

- By accelerated roll out of electrified mobility through increased attractiveness for citizens and businesses, offering lower prices, better performance and safety, reliable operation of e-vehicles. Increased grid flexibility, increased share of renewables integration, and facilitated self-consumption and participation in energy markets by citizens and businesses.

- In increasing the overall sustainability and improved Life Cycle Assessment of each segment of the battery value chain.

Objectives

1. Develop hybrid oxide-sulfide composite ceramic electrolytes.

Develop a novel, stable, high performing and up-scalable hybrid oxide-sulfide composite ceramic electrolytes when in contact with a protected thin metallic lithium anode. To do so, the synthesis, processing, modelling and experimental validation of different combinations of oxide and sulfide materials will be carried out.

2. Develop an optimised Li anode composed of thin lithium metal films.

Develop an optimised Li anode composed of thin lithium metal films deposited by thermal evaporation on top of copper current collector foils, with high stability, along with a protective layer.

3. Develop solid nickel rich NMC-based high performing cathodes.

Develop solid nickel rich NMC-based high performing cathodes. This will lead to the demonstration of stable, safe and highly performant 10 Ah pouch cells.

4. Demonstrate stable, safe and performant 10Ah pouch cells

Demonstrate stable, safe and performant 10 Ah pouch cells using an oxide-sulfide hybrid electrolyte, a Ni-rich cathode and a thin lithium metal anode in a pilot line.

5. Develop new combined operando characterisation techniques.

Develop new combined operando characterisation techniques, which will allow materials and interface optimisation by the in-situ observation of the changes taking place in realistic operation conditions.

6. Develop safer handling and recovery of various metals.

Develop safer handling and recovery of various metals through sustainable recycling process.

7. Develop a plan to market supported by strong collaboration.

Develop a plan to market supported by strong collaboration through Mission Innovation and targeted communication and dissemination. ADVAGEN will ensure that the project results will be disseminated and exploited to a wide and relevant audience and in particular in the EU.

Consortium

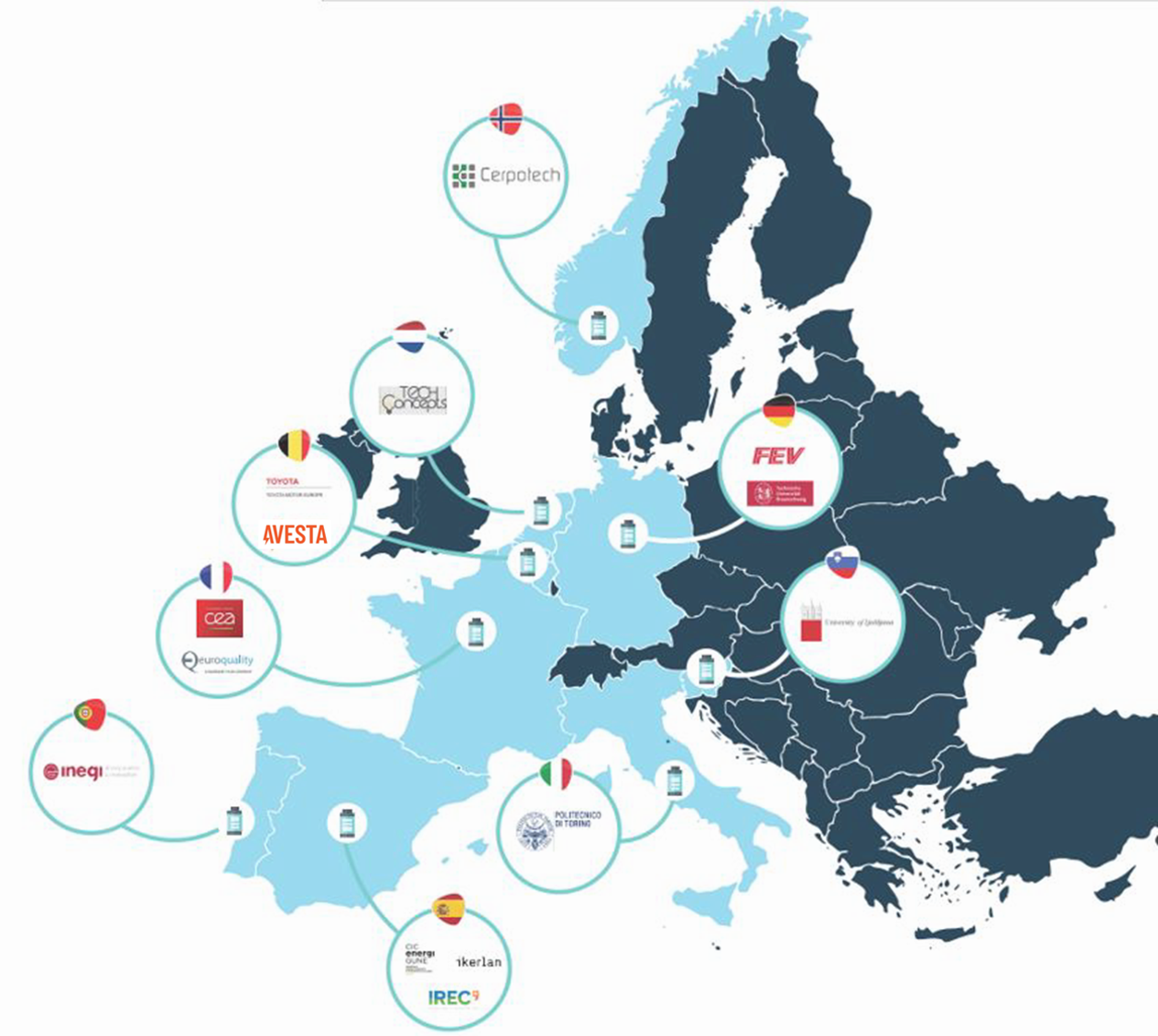

The ADVAGEN consortium consists of a transdisciplinary consortium of 14 partners from 9 countries, with extended experience in the development of battery technology and production, from industrial materials producers (CPT), battery manufacturer (AVESTA) to R&D centers (IKE, CEA, IREC, TUBS, CIC, energiGUNE, POLITO, INEGI, UL, FEV) and the automotive industry (TME), covering the complete knowledge and value chain.